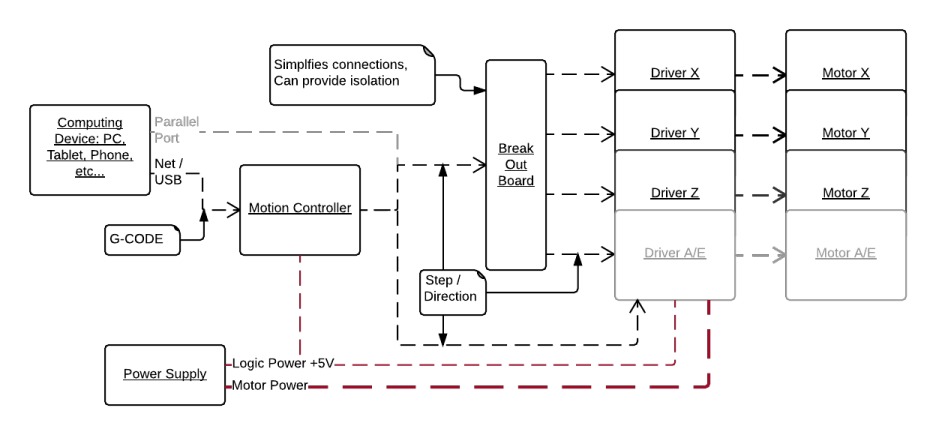

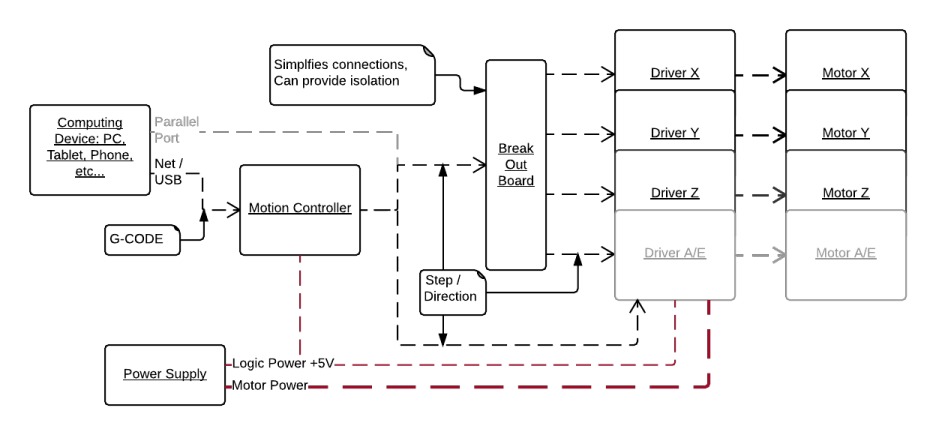

Motion Control provides signals in real time that direct the motion of motors via drivers, typically sending step and direction signals to the drivers which then apply power to the motors to cause the desired motion. A Motion Controller must plan a motion profile which will move the load from the current position to the desired position while accomodating the mass of the load vs the power of the motors (via accelleration or ramping), and mange the coordiation of multiple axis when the load is being moved in 2 or 3 diminsions. E.g. to cut a straight line from 2,2, to 4,3 the X and Y axis must move together smoothly but not at the same speeds.

Computer Numerical Control applications typically provide motion control for CNC machines, but as standard operating systems are NOT design for real time control, it can be best to use a seperate Embedded Motion Control Device. In robotics applications motion control can be much more complex.

Stepping Motion Profile Motion panning overview. Stepper motor specific, but with good general information.

A common language for specifying the desired location and speed of movement is G-CODE

See also:

| file: /Techref/method/motioncontrol.htm, 2KB, , updated: 2021/9/3 10:22, local time: 2025/10/23 08:48,

216.73.216.20,10-1-5-169:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://ecomorder.com/techref/method/motioncontrol.htm"> Motion Control Methods</A> |

| Did you find what you needed? |

Welcome to ecomorder.com! |

|

The Backwoods Guide to Computer Lingo |

.